Harsh and Hazardous Location lighting Manufacturer

[email protected] +86-25-85508029

Submit a Request

Definition of hazardous area classification (ATEX&IECex)

Definition for hazardous locations in North America

In North America, hazardous locations have traditionally been defined by a combination of classes and divisions as follows:

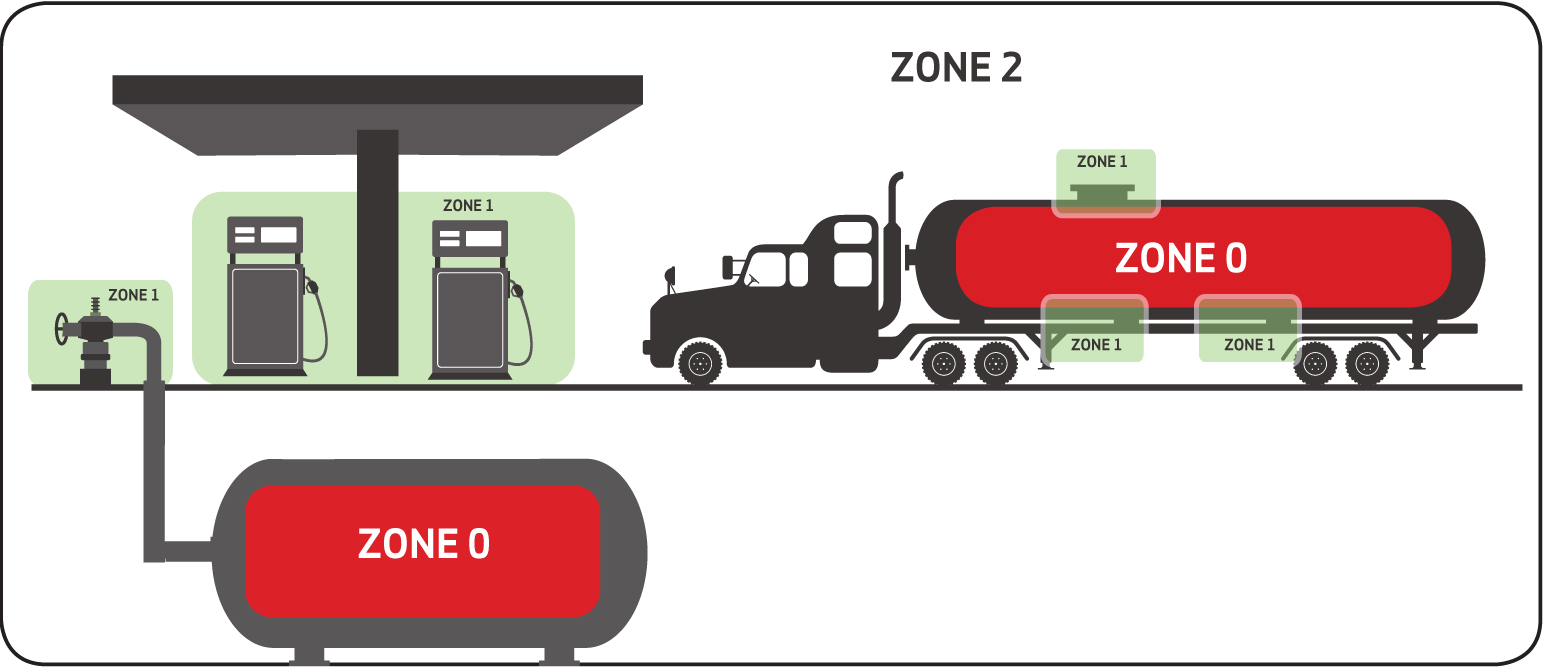

- Zone 0: An area in which an explosive gas atmosphere is present continuously or for long periods;

- Zone 1: An area in which an explosive gas atmosphere is likely to occur in normal operation;

-

Zone 2: An area in which an explosive gas atmosphere is not likely to occur in normal operation and, if it occurs, will only exist for a short time.

Various sources have tried to place time limits on to these zones, but none have been officially adopted. The most common values used are:

- Zone 0: Explosive atmosphere for more than 1000h/yr

- Zone 1: Explosive atmosphere for more than 10, but less than 1000 h/yr

- Zone 2: Explosive atmosphere for less than 10h/yr, but still sufficiently likely as to require controls over ignition sources.

ATEX zones for dusts

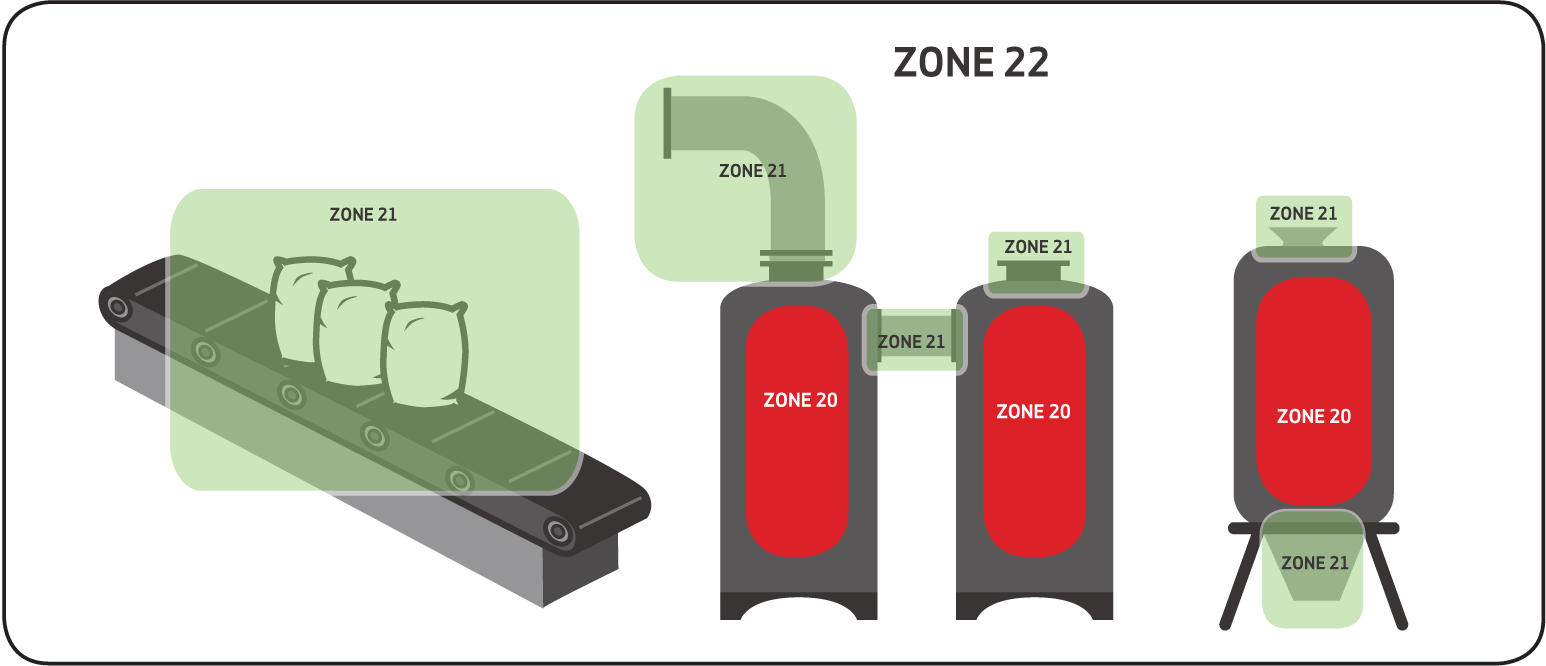

Dust clouds in the explosive region (above the minimum explosible concentration) are categorised into 3 zones, based upon the grade of release

Zone 20

Continuous release inside a dust containment enclosure gives rise to Zone 20 - a place in which an explosive atmosphere, in the form of a cloud of combustible dust in air, is present continuously, or for long periods or frequently for short periods. For example, a mill or pneumatic conveying system.

Zone 21

Primary grade of release gives rise to Zone 21 - a place in which an explosive atmosphere, in the form of a cloud of combustible dust in air, is likely to occur occasionally in normal operation. For example, bagging points and inspection ports that are frequently opened.

Zone 22

Secondary grade of release gives rise to Zone 22 - a place in which an explosive atmosphere, in the form of a cloud of combustible dust in air, is not likely to occur in normal operation but, if it does occur, will persist for a short period only. For example, leaks from incorrectly fitted lids or spillages.