Submit a Request

A Case of High Temperature Lighting in a Mechanical Company's Facility

As the saying goes, "Dog days are very hot", especially in the applications like metallurgy, die-casting and machining industries that might resemble a huge steamer. In here, more heat is absorbed every day with small amounts of dissipation and greater accumulation of heat on the surface layer, so it is hotter every day.

Especially in steelmaking facilities and rolling mills, due to process requirements, will use water to cool the refining billets, and the high temperature combined with the water will bring the two regions together with high temperature and water vapor. A large amount of heat is generated every day; the closed environment of the facilities’ environment is poor, and the ambient temperature during the day can reach 70 degrees or more. We can feel the high temperature in the steel mill through the following pictures.

Lighting fixtures are indispensable equipment in steel mills, but the high temperature and high water vapor in these hazardous locations is also a major killer of lamps. The high temperature will reduced the life of the lamp source and the light decay will be accelerated. When the temperature exceeds a certain value, the lamp will not be bright, which will seriously affect the production. High water vapor will accelerate the corrosion of the surface of the lamp, and will also cause some poorly-protected lamps to be off. We can use the following figures to see the damage caused by high temperature and water vapor to lighting fixtures.

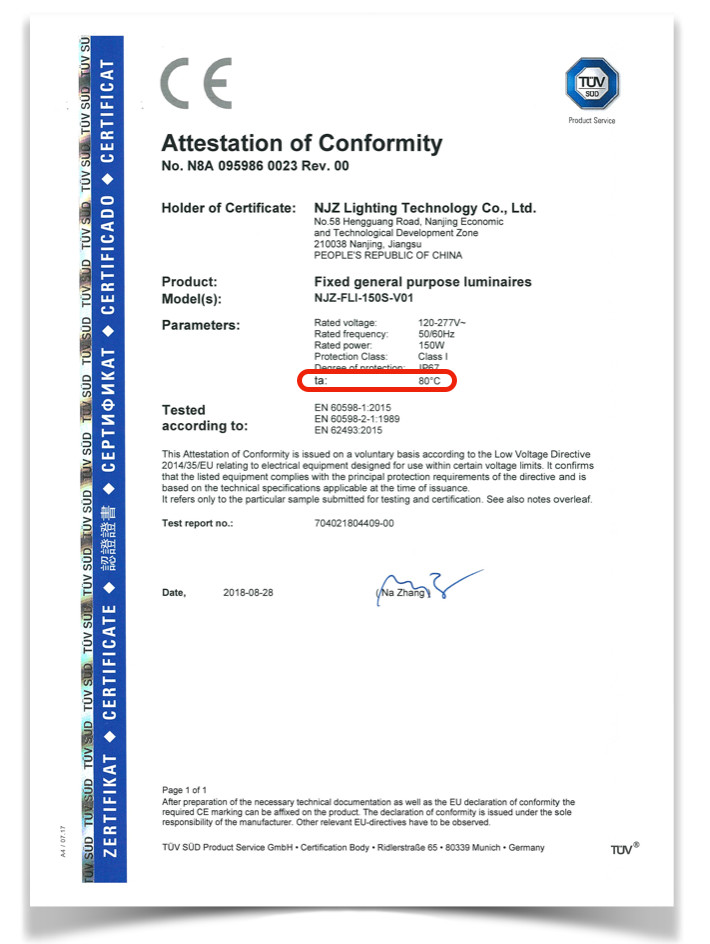

In response to such high-temperature use environment, NJZ Lighting has been developing high-temperature lighting products since 2017. It lasted for one and a half years until we introduced two high-temperature environments: NJZ-FLI (80℃) and NJZ-FLH (70℃) in 2018. The lighting fixtures, after a series of high-standard tests, finally obtained the high-temperature factory lighting certification issued by TUV. As shown below:

FLI 80 ℃ and FLH 70 ℃ series high temperature factory lights

Authorized certification body TUV awarded 80 °C ring temperature application certificate

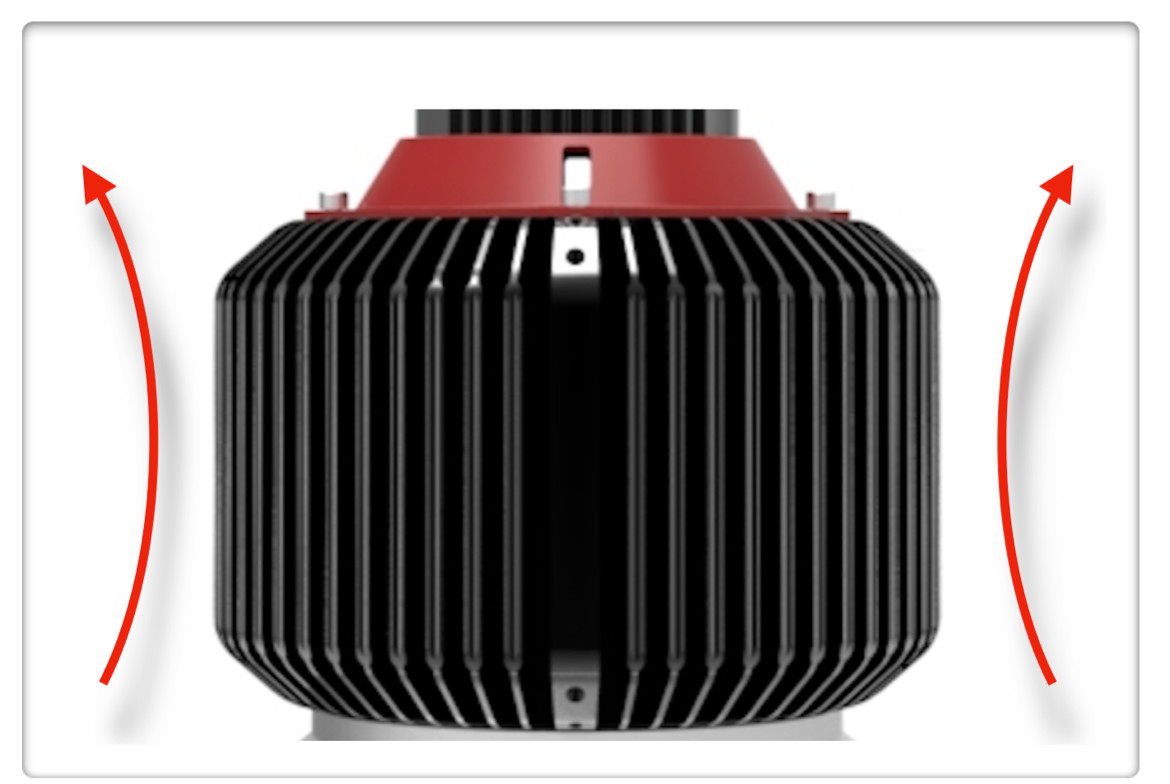

NJZ-FLI and FLH series high-temperature lighting uses a star-shaped high-density liquid-channel structure LED heat sink, including negative pressure sealed evaporator such as special phase change medium, and heat sink with high thermal conductivity metal material, heat sink back processing The liquid guiding channel with a certain capillary force is sequentially arranged with a concave hole capable of accommodating a certain amount of liquid on the high-density liquid guiding channel, and the outer surface of the heat sink is provided with a plurality of fins for increasing the heat exchange area.

Such a complicated heat dissipation design can effectively improve the heat dissipation efficiency and improve the operational reliability of the equipment.

Heat pipe phase change radiator

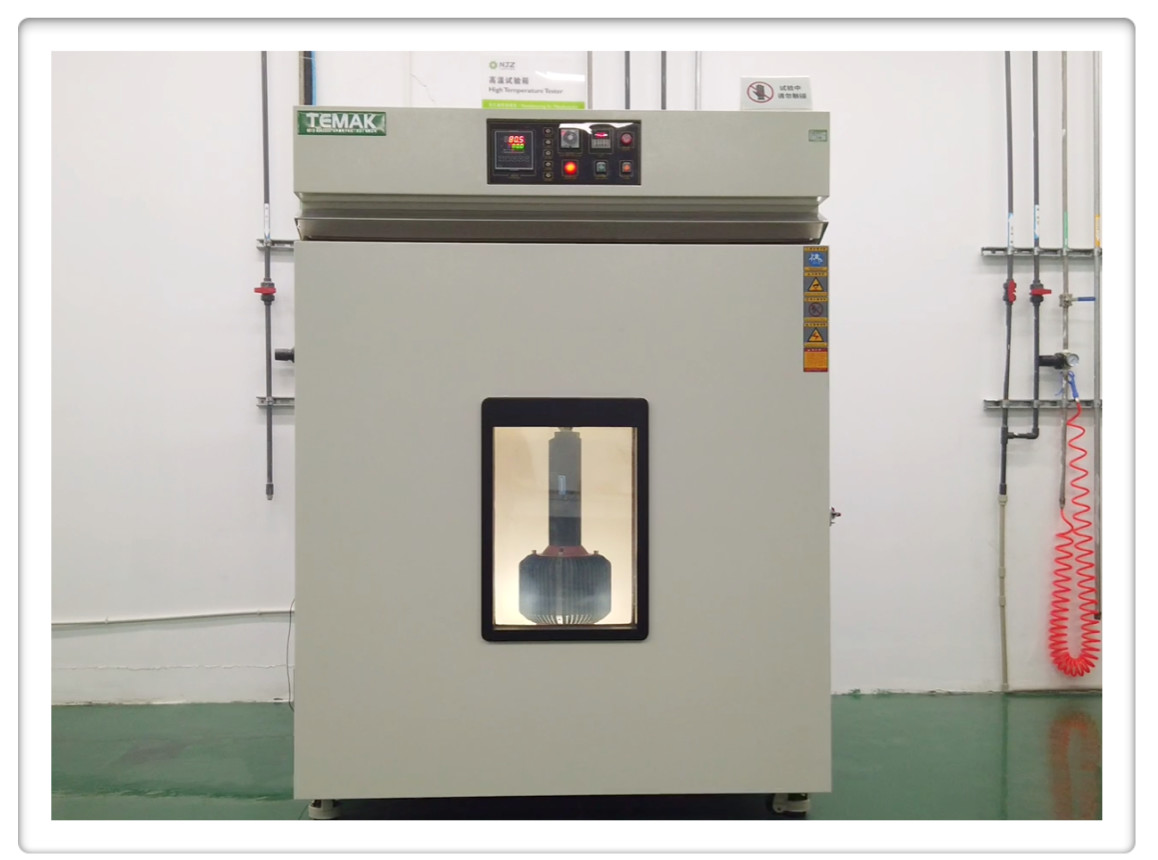

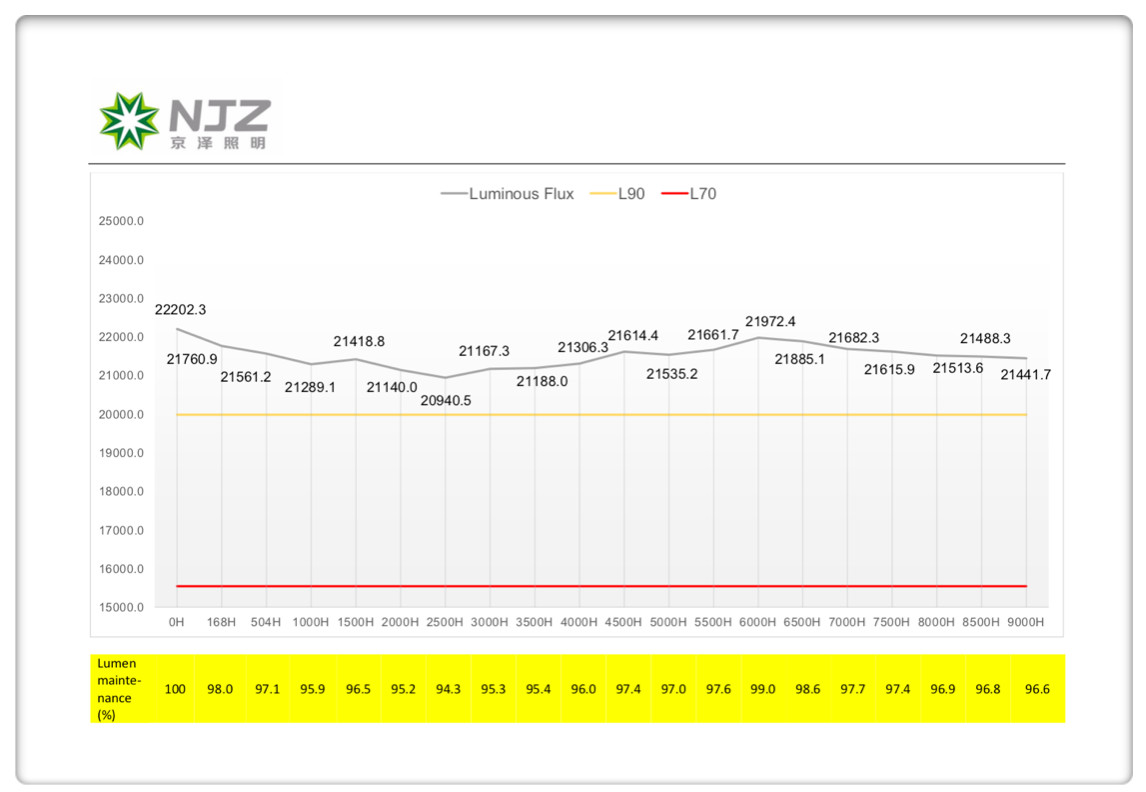

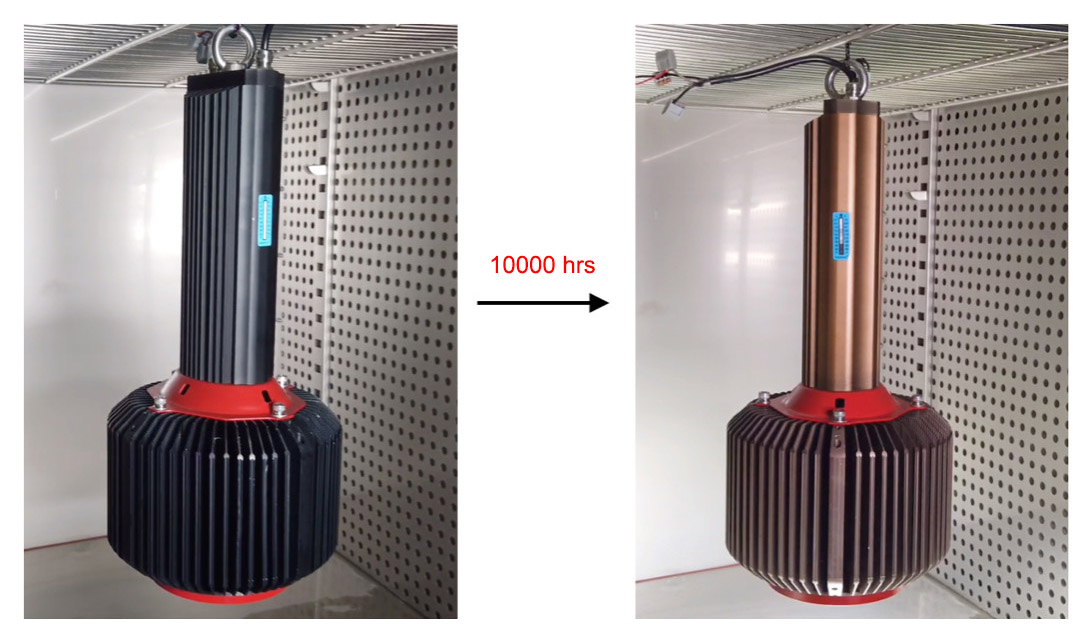

At the same time, in order to verify the luminous efficacy of the luminaire in the 80℃ environment, we have done 10,000 hours of long-term high temperature aging light decay test. As shown below:

10000 hours high temperature accelerated aging light failure test

Nearly 10,000 hours of 80℃ aging, less than 4% attenuation

Heat treatment workshop site photo

The black color of the exterior was baked into a bronze color, and the temperature-sensing label on the power supply chamber reminded him of the "baked" test he had experienced in this 10,000 hours. Nearly 10,000 hours of continuous high temperature aging, FLI's actual light decay is 3.4%, and its excellent performance perfectly reflects the advantages of its thermal design.

Finally, we present a actual case study of a heat treatment in a mechanical company facility in Nanjing.

The facility is mainly based on the quenching and tempering treatment of the gear parts. The indoor temperature is above 50℃, and the highest temperature in the summer ceiling is up to 75℃. Before replacing the high-temperature factory lights of NJZ Lighting, the facility had to change the lighting equipment twice a year, causing losses and delaying production efficiency. After the trial of FLI products, since the installation in the summer of 2018, the 32-inch 150-watt lamps are still "smirking high temperature"!