Harsh and Hazardous Location lighting Manufacturer

[email protected] +86-25-85508029

Submit a Request

Flammable and Explosive Dust in Hazardous Locations

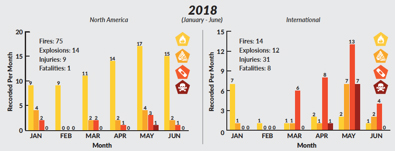

Quality light in a hazardous location is necessary, but it could also be dangerous. Knowing the facilities, and the compositions that can be found in the location allows a proper, and safer work environment. Several episodes of explosive dust have been reported and affected industries throughout the world, some of which have caused huge losses. Any gas explosion is the result of the presence of flammable gas, the presence of oxygen, a mixture of the last two and an ignition source. Explosions usually take place inside of the equipment (primary explosion), but the most severe consequences are usually caused by explosions outside of the equipment (secondary explosion). Dust explosions almost always lead to serious financial losses, injuries, and fatalities.

Some of the materials that can cause dust explosions are grain, wood, linen, sugar, synthetic, plastics, organic pigments, pesticides, pharmaceuticals, coal and peat, and metals (aluminum, magnesium, titanium, zinc, iron, etc.). Some of these materials are not flammable but they can burn or explode if the particles are the right size and in the right concentration. Some of the last year serious explosive dust incidents include: Gran Silo Explosion (Port Aqaba, Jordan), Grain Elevator Explosion (South Sioux City, NE), Fluid Bed Dryer Fire (Madhya Pradesh, India), Metal Dust Explosion (Changhua, Taiwan). The number of explosions increases every year, so it is critical for any hazardous area to reduce the risk of dust explosions. These include strict adherence to maintenance and usage of certified equipment.

Source: Dust Safety Science.com

According to the agencies that regulate lighting in hazardous environments the Class designation describes the type of materials that may be present, including gas, liquid produced vapors, dust, and fibers. Class I present natural gas, petroleum, and chemical while Class II locations contain combustible dusts, such as starches, flour, and wood flour. The category of Division defines the probability that those materials will be present to form flammable or combustible fuel-air mixtures.

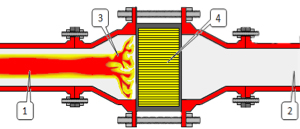

Fixtures placed within the UL classification must ensure that ignition is never allowed into the environment; explosion-proof fixtures feature “flame-paths” that allow the gases to escape to the outside atmosphere only after the gas has traveled and cooled within the fixture. The maximum temperature of the exposed surface of these fixtures is a determinant factor for them to be able to disarm inside themselves; they are classified as flameproof, explosion-proof (T- rating on the exterior of the fixture), enclosed and gasketed (T-rating on the inside of the fixture) and restricted breathing (T-rating on the surface of the fixture).

1. Exposed Side 2. Protected Side 3. Flame stabilized on arrester element 4. Flame-path element absorbs and quenches flame front

Dust explosions represent a serious concern to chemical processing and manufacturing industries. That’s why it is important to design and manufacture fixtures that reduce the amount of heat they produce to prevent the occurrence of dust explosions, or to mitigate the potential consequences. NJZ Lighting fixtures for hazardous locations are designed to specifically work under high explosive dusts, flammable gases, and vapors that are common to the hazardous locations industries.