Harsh and Hazardous Location lighting Manufacturer

[email protected] +86-25-85508029

Submit a Request

The historical evolution from industrial and mining lamps to explosion-proof lamps

The first industrial revolution took place and mankind entered the age of steam. As productivity progressed, mankind's need for energy skyrocketed - the potential of coal was gradually explored.

Facing one pit after another, lighting in the pit became a problem. At first, the miners used candles, which solved the problem of lighting, but created another problem: fires and explosions.

Coal mines are rich in methane and when exposed to open fire, an explosion occurs in the relatively confined cavern. Even more serious is when methane explodes, the explosion often consists of an initial explosion leading to the burning of a coal dust cloud, which in turn produces a more violent dust explosion (dust explosion).

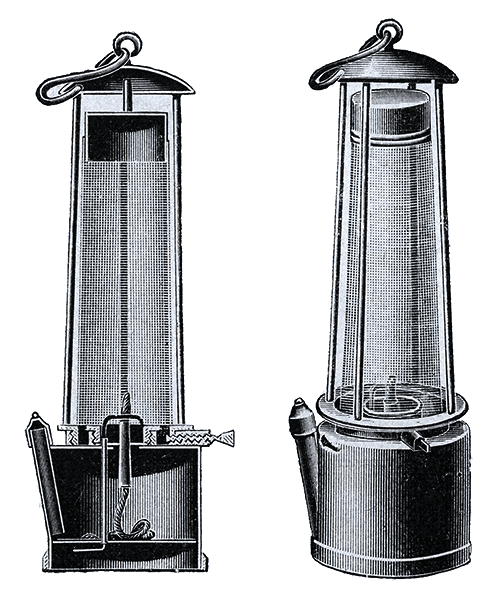

In 1815, The first fuel safety light is invented, also known as the Davy, Geordie, and Clanny lamps – were designed to cool the air surrounding the flame to a temperature below the firedamp ignition point while still allowing the air to pass freely using a wire mesh enclosure or the restriction of the amount and rate of intake airflow and exhaust through a system of fine tubes and a glass cap shield with a gap at the bottom or a combination of these methods.

Davy lamp

The Davy lamp seemed to provide the necessary safety for the ignition of all methane gases, but after many explosions in the mines where it was used, it soon proved that it was not perfect. that it is not flawless and that it can only reduce the chance of an explosion, not prevent it in all cases. In particular, it has the following disadvantages:

• The ignition of a mixture of gas and hydrocarbons will appear to pass through the metal canvas and there is a fast rapid flow of air, because of which the flame of the lamp reddens the mesh or passes through it.

• The slightest vibration can cause deformation or even tear the mesh open, rendering the light ineffective. The light does not work.

• This metal mesh comes into contact with the tank and is quickly lubricated and carries fuel dust, thus forming an internal a slurry that can be ignited on the outside.

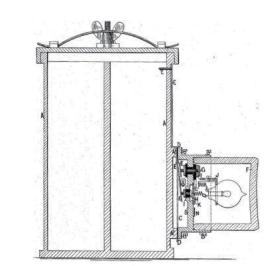

In 1842 the Liège engineer Mathieu-Louis Mueseler invented a lamp with the following advantages lamp:

• When a large amount of explosive gas, even pure hydrogen, is mixed, it will extinguish quickly.

• It is best irradiated, can be placed away from workers and requires no tools, and is best used in passages with strong air currents.

• The wire mesh, which is removed from the tank, does not penetrate into the oil. It can only stick to dry dust but is easily removed.

• It has two wire screens, one horizontal and the other vertical, so that when one breaks, the other remains intact.

• Finally, the airflow activates combustion from top to bottom, rather than being activated from the sides, providing the inestimable advantage of all other popular safety lamps, which suddenly switch off when there is enough hydrocarbon in the air to supply an explosive mixture.

Mueseler lamp

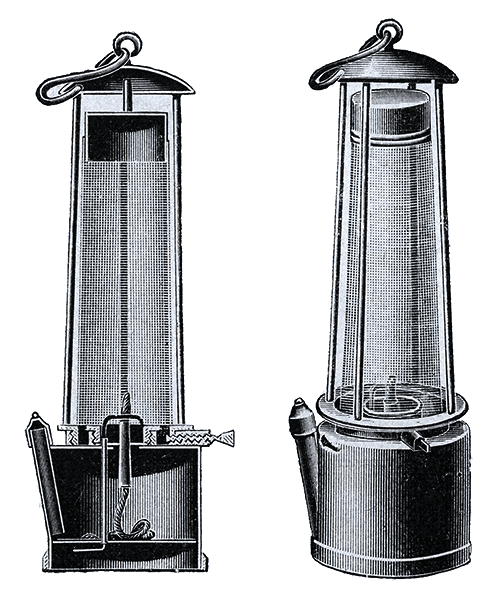

In 1864, it was legislated by the Belgian government legalized for use. It was then adopted by the French and British mines.However, it has shortcomings and there are still problems to be solved: If accidentally extinguished, this forces it to exit the well and relight.In the 1990s, paraffin replaced oil and electronic ignition systems began to appear.The first portable electric lamp with batteries was invented by Mr Dumas and Mr Benoit at the Paris Academy of Sciences in 1862.

Electric lamp with batteries

In 1884, an Englishman from Morin Gate, England Theophilus Cad invented an electric lamp with a switch fitted into in what is considered the first electrically isolated housing.

However, shortly after the introduction of electricity in coal mines, it was also discovered that fixed electrical equipment, such as lighting, signals or motors, could cause fatal A fatal explosion.In 1913, 439 miners were killed in a massive explosion at the Senghenydd coal mine in England. Explosion suspected to be caused by sparks from exposed wires used in alarm system.Following this case, the miners demanded the removal of the mine's electrical equipment. Then came the development of "explosion-proof" electrical equipment, where the inevitable sparks could only occur in a protective layer to prevent ignition of the surrounding gases.

The subject of hazardous (classified) locations first appeared in 1923 in the US National Electrical Code (NEC).In Europe, the first German standard "Protection of electrical installations in hazardous areas" was published in 1935 and gives guidelines for the installation of electrical equipment in hazardous areas.In the 1960s, the EU was founded and CENELEC was set up to harmonise technical specifications.In 1972 a new set of European standards (EN50014 - EN50020) was published which described equipment for use in explosive atmospheres. The first EU directive for equipment used in hazardous areas was published in 1975 and is known as the "Ex Protection Directive".

At the same time, countries around the world enacted their own explosion-proof standards for electrical appliancesThese set the stage for modern explosion-proof equipment and are the barriers to entry for the explosion-proof lamp industry.

Facing one pit after another, lighting in the pit became a problem. At first, the miners used candles, which solved the problem of lighting, but created another problem: fires and explosions.

Coal mines are rich in methane and when exposed to open fire, an explosion occurs in the relatively confined cavern. Even more serious is when methane explodes, the explosion often consists of an initial explosion leading to the burning of a coal dust cloud, which in turn produces a more violent dust explosion (dust explosion).

In 1815, The first fuel safety light is invented, also known as the Davy, Geordie, and Clanny lamps – were designed to cool the air surrounding the flame to a temperature below the firedamp ignition point while still allowing the air to pass freely using a wire mesh enclosure or the restriction of the amount and rate of intake airflow and exhaust through a system of fine tubes and a glass cap shield with a gap at the bottom or a combination of these methods.

Davy lamp

• The ignition of a mixture of gas and hydrocarbons will appear to pass through the metal canvas and there is a fast rapid flow of air, because of which the flame of the lamp reddens the mesh or passes through it.

• The slightest vibration can cause deformation or even tear the mesh open, rendering the light ineffective. The light does not work.

• This metal mesh comes into contact with the tank and is quickly lubricated and carries fuel dust, thus forming an internal a slurry that can be ignited on the outside.

In 1842 the Liège engineer Mathieu-Louis Mueseler invented a lamp with the following advantages lamp:

• When a large amount of explosive gas, even pure hydrogen, is mixed, it will extinguish quickly.

• It is best irradiated, can be placed away from workers and requires no tools, and is best used in passages with strong air currents.

• The wire mesh, which is removed from the tank, does not penetrate into the oil. It can only stick to dry dust but is easily removed.

• It has two wire screens, one horizontal and the other vertical, so that when one breaks, the other remains intact.

• Finally, the airflow activates combustion from top to bottom, rather than being activated from the sides, providing the inestimable advantage of all other popular safety lamps, which suddenly switch off when there is enough hydrocarbon in the air to supply an explosive mixture.

Mueseler lamp

Electric lamp with batteries

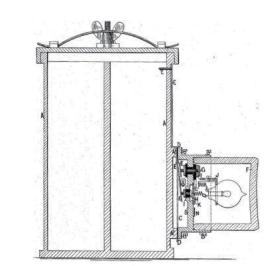

In 1884, an Englishman from Morin Gate, England Theophilus Cad invented an electric lamp with a switch fitted into in what is considered the first electrically isolated housing.

1884 Cad electrical lamp

However, shortly after the introduction of electricity in coal mines, it was also discovered that fixed electrical equipment, such as lighting, signals or motors, could cause fatal A fatal explosion.In 1913, 439 miners were killed in a massive explosion at the Senghenydd coal mine in England. Explosion suspected to be caused by sparks from exposed wires used in alarm system.Following this case, the miners demanded the removal of the mine's electrical equipment. Then came the development of "explosion-proof" electrical equipment, where the inevitable sparks could only occur in a protective layer to prevent ignition of the surrounding gases.

The subject of hazardous (classified) locations first appeared in 1923 in the US National Electrical Code (NEC).In Europe, the first German standard "Protection of electrical installations in hazardous areas" was published in 1935 and gives guidelines for the installation of electrical equipment in hazardous areas.In the 1960s, the EU was founded and CENELEC was set up to harmonise technical specifications.In 1972 a new set of European standards (EN50014 - EN50020) was published which described equipment for use in explosive atmospheres. The first EU directive for equipment used in hazardous areas was published in 1975 and is known as the "Ex Protection Directive".

At the same time, countries around the world enacted their own explosion-proof standards for electrical appliancesThese set the stage for modern explosion-proof equipment and are the barriers to entry for the explosion-proof lamp industry.